04 Oct Product Test – Pivot Works Wheel Bearings

Company: Pivot Works

Price: $24.95 to 69.95

- Kits are all inclusive.

- Fit is perfect, as if they were OEM.

- Last as long as OEM.

- Waterproofing O-rings can tear or fall out, slight drag in quick wheel changes.

- Remembering which bearing is in the wheel for replacement (between upgrade kits.)

What it is

- Replacement Wheel Bearing kits with all the seals and bushings.

Pivot Works has been around for a long time and is one of the companies part of a larger group of brands that make replacement wear parts for dirt bikes. It’s goal was to be the complete solution to bearing and chassis maintenance for dirt bikes and ATVs. Pivot Works’ kits contains all the necessary components (bearings, seals, pins, spacers, collars, thrust washers and thrust bearings) needed to rebuild each part of the suspension system and chassis to make it easy for the owner. In 2012, Pivot Works established a Lifetime Replacement program on all of its products.

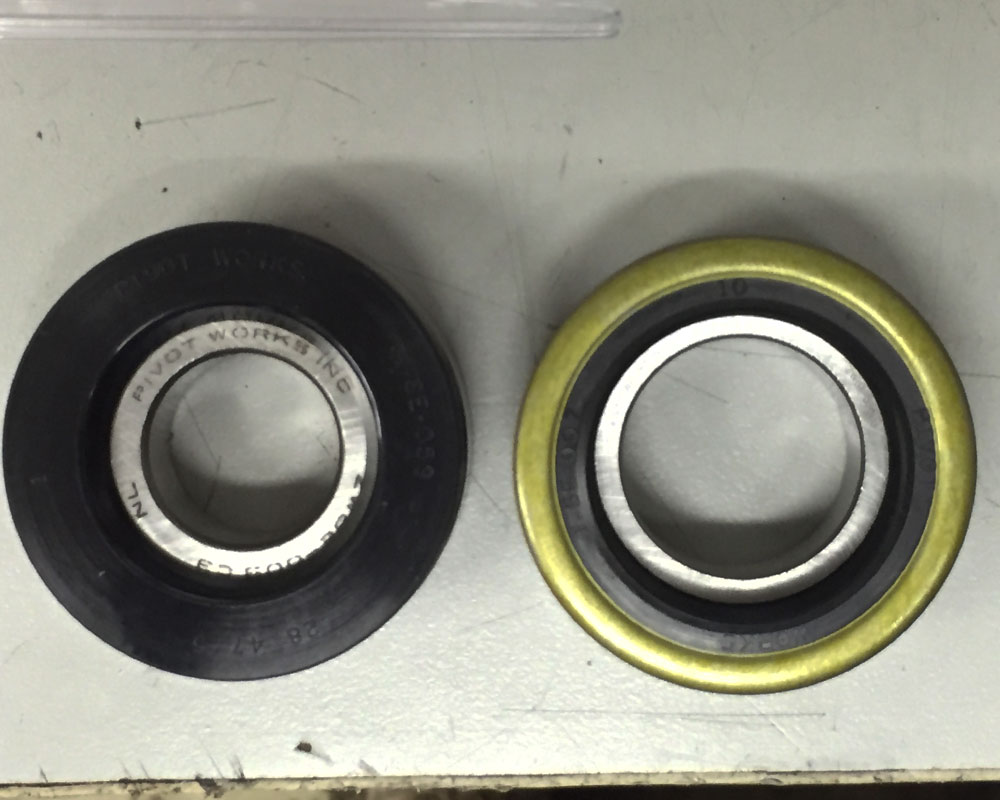

Pivot Works kits are claimed to meet OEM standards for quality, durability, and fit. Their wheel bearings use a double sealed design where some OEM may only be a single sealed bearing. The list of applications is extensive and is updated for new bikes typically before you’d ever need a replacement bearing.

How it works

- Exceptional durability.

- Solid fit.

- Easy to install.

- Waterproofing O-Rings.

We have been using Pivot Works bearings kits in our personal bikes and in a rental fleet for a long time now. Well over 15-years and with lots of success in fit and durability. The biggest advantage of the Pivot Works kits is that they are one-stop, all inclusive and made to do the job right. Most of the time they are priced comparable or even a little less than OEM parts including the upgraded wheel spacers and larger bearing upgrade kits.

Specific to the wheel bearing kits and in our use on many KTMs, the Pivot Works kits last as long as standard OEM bearings and this includes the seals and collars too. And if you know the quality of the KTM parts, specifically the collars and seals, this is a good thing. We are mostly in a dry environment so our life cycle for bearings is generally pretty high, but everything is relative. We do ride in some very alkali mud and our water is harsh on metal. And when near the coast, we have some slight humidity but nothing like some areas. We have also learned that humidity tends to be the biggest factor in wheel bearing life–aside from abuse. Our testing included plenty of high-water river crossings and mostly unintentional abusive pressure washing.

The instilation is just like standard and fit was perfect on every kit. We tested both standard replacement parts and also the special oversized rear wheel bearing kit made for KTMs. This kit uses slightly larger bearings, an upgraded spacer inside the center of the hub and thinner seals and wheel spacers to make it all fit. Additionally, the circlip is left out to provide additional space for the bearings. We used all methods of removal and instillation, from claw hammers and screwdrivers to proper bearing instillation tools and we feel almost anyone with minor mechanical knowledge can accomplish this task. Upon reassembly we were generous with the grease, especially between the outer side of the bearing and the collar up under the seal. We also made sure the O-ring on the waterproof collar was lubed up good to prevent tearing.

Our rear wheel bearings on KTMs have been lasting an average of four years, which is how long we are getting out of stock parts that were standard on the bike and stock bearings as a replacement as well. So in our book durability is the same as stock. This is a big fear for some riders and is understandable. When Pivot Works bearings wore out, it was a slow process where the wheel would slowly get loose and have a slight amount of side-to-side play but still spin just fine. We even let some go a little long to see if there would be a serious failure and it never happened. If you feel any slop in the bearings, something that is easy to feel with the bike on a stand, it is time for replacement.

The added O-ring to provide waterproofing is a great idea and has benefits if you axle has any wear on it, generally corrosion. Or if the axle to collar fit is not tight, but this has never been a problem on our KTM’s. None of our axles were in this type of poor shape. Over time we did not notice any difference or benefit from the O-rings being in the collars when it came to waterproofing. In fact, in the name of testing we blasted both Pivot Works and stock setups with a high-power pressure washer to see if the O-rings prevented water from sneaking into the wheel’s center between the axle and collar. There was no difference in water getting in along the axle, none did in either setup. There was one exception in that the O-ring would “wipe” the water off the axle if it was wet when disassembling and not allow water to be dragged into the wheel as easily.

Incidentally in this abuse we found that brand new wheel collar seals (stock or Pivot Works) also prevent water from getting in at the seal lip. Wheels that were used–and in our world about a year old–would allow water past and if there wasn’t plenty of grease in the cavity between the collar and bearing, the water will live in here and eventually get to the bearing causing rust.

The O-ring provides a slight increase in friction so those interested in quick wheel changes may want to leave them out. The O-rings do wear over time and will need to be replaced, especially if wheel changes are common or they are let to get dried out. Forcing the axle will chip and tear at the O-rings. The kits come with a spare set.

What we have found over time is that the seals are the first wear item, even if they look good. Heat, friction and abrasion all take life out of the seal and eventually it does not take much for water and sediment to get past and start the journey to the bearings’ balls and rolling surfaces (also protected by a seal.) When in a humid environment, the moisture has an easier time getting into the contact areas of the bearing. After time even sealed bearings are no longer sealed and the grease has separated and left some metal vulnerable. No matter what, this will happen and it depends on your conditions and your maintenance schedule. After the seals harden with time they will also begin to wear the collar. Assembling the seal to the proper depth (usually flush with the hub) will keep it riding on the proper part of the collar. Dented seals and those that have been improperly installed can run on the wrong place on the collar and not create a proper seal. And worn collars will never seal, even with new seals. Another reason for the full kit approach.

The wider wheel bearing kit also did not show any significant differences in lifespan or durability even with larger balls and races. There was one big exception. Older KTM wheels (generally the smaller hubs) had a run of inner bearing spacers that were made from thin aluminum tubing. Over time and through over torquing of the rear wheel, these tubes will compress and allow too much pressure on the hub, casuing the bearing and often the hubs to fail. The Pivot Works kit has a much more robust spacer in the kit and it will save you the cost of a hub and wheel lacing. We felt that since the bearings life expectancy was based on water getting to them, the larger bearing size did not seem to matter. The only other drawback to the oversize kit is that the collars (also with waterproofing O-rings) are not as encased into the bearing so during wheel instillation the collars are easier to knock out of the seals like on many Japanese bikes. On the standard kit, the spacers are long and ride into the bearing so they will not slide or fall out. Also you need to remember that you have upgraded to this kit when you replace the bearings and seals a few years down the road. Yes we were scratching our head when the standard replacement kit looked different till we remembered that this was the upgraded one.

Some additional notes from our bearing testing. We have also gone to the bearing supply house and auto parts stores on different occasions and replaced just the bearing in a wheel. Our notes indicated that these bearings wore out within a year or two and we could attribute that to the quality of the bearing (hard to prove) or more likely since the seals and collars were not replaced the bearing was subjected to the elements much more quickly. This also makes sense in buying these parts in a kit.

Our take is that the Pivot Works bearings and seal kits are a solid choice when it comes time to replace worn wheel bearings. As long as you go with the complete kit (including spacers every time) you will have a like-new fit on the axle. The quality of the materials is up to doing the task as good as OEM. We are fine with that. Even if some of the extra features didn’t really provide big benefits, they didn’t have many drawbacks either. Pivot Works also offers a one-time lifetime replacement of a kit if there is a failure. But be warned that is the lifetime of a bearing and that is a very subjective call, though we would suspect that any sub-standard issues with a wheel bearing would show up rather quickly and be handled fairly. Over time we have gone through over 15 kits (on 12 different bikes) and have had nothing but success and never a failure.

Sorry, the comment form is closed at this time.